We demonstrated at 1997 and Now our head office at Pune- Western India Multi storeyed modern corporate office & design Hub for all KBK Engineering services across the globe

Our Directors

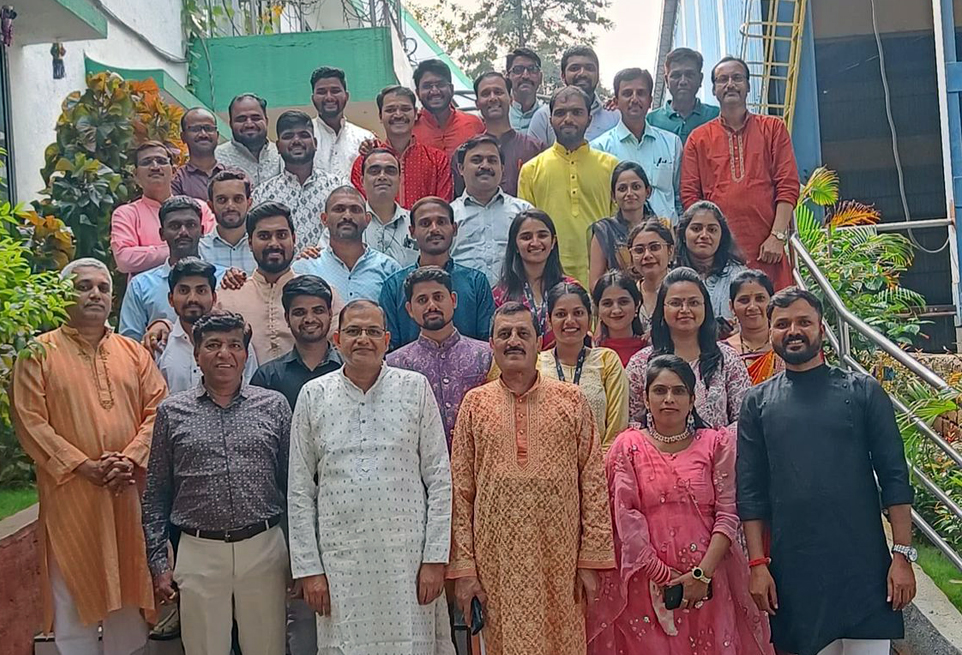

Our Team

KBK Chem-Engineering Pvt Ltd, Pune is India’s one of the leading EPC Solution and Technology provider for Distilleries, Bio-ethanol,, Brewery, Sugar, Chemical processing, Edible Oil, Fish Meal processing and Co-generation plants with Efficient Management along with Water and Waste Water solutions.

KBK has executed over 90 projects globally and is a popular name in the field of distillery not only in India but also in many countries abroad including INDIA, BRAZIL, MOROCCO, BULGARIA, UKRAINE, SENEGAL, UGANDA, ETHOPIA, SRILANKA, THAILAND, MYANMAR, VIETNAM, PHILLIPINES, INDONESIA, MALAYSIA, SOUTH AFRICA, ZAMBIA, TANZANIA. KBK has a unique distinction of working with various feed stock for the distillery like molasses, sugarcane juice, sugar beet juice, grain and sweet sorghum juice.

Established in 1997, KBK has indigenously developed ‘K-Super’ & ‘K-M@S’ technology and executed number of EPC projects in India, Asia, Africa & South America. KBK has accomplished many EPC projects of Distillery, Fuel Ethanol, Chemical Process Plant with its INDIGENOUSLY DEVELOPED K-SUPER TECHNOLOGY and world class manufacturing facilities complete Project Management, Engineering, Manufacturing, Erection and Commissioning of various prestigious National and International clients spread across the world.

Work Shop

ISO-9001-2015 approved Workshop Facilities having capasity of more than 300 MT SS/MS fabrication per month.

Manpower Profile

Highly qualified manpower comprising of Alcohol technologist, Chemical engineers, Mechanical engineers, Electrical engineers, instrumentation engineers and Civil Engineers, Bio-technologist, Power plant engineers, Waste Water Treatment engineers etc.

Area of Business

Distillery, Ethanol, Bio-fuels, Chemical Processing Equipments, Edible Oil equipments,Cogeneration Power plants, Sugar plant process house equipments, Sugar Refinery process house equipment’s, Edible Oil Refinery equipments, Petro chemicals plant equipments etc.

Product Lines

EPC turnkey plants for Potable grade alcohol (RS / EQRS / ENA), Fuel grade Ethanol, Alcohol derivatives, Cogeneration power plants, Water Treatment Plant & Waste water management plants, Sugar plants & Sugar equipment’s etc.

Raw Material

Sugarcane Molasses, Sugar Cane Juice/Syrup, Sugar Beet Juice, Grains like Corn (Maize), Broken Rice, Sweet Sorghum& Bajra Cassava &Tapioca

Engg Standards

Equipments are designed as per the following Engineering Standards:

European Standard, American Standard, British Standard, Japanese Standard, Indian Standard